Workshop Services

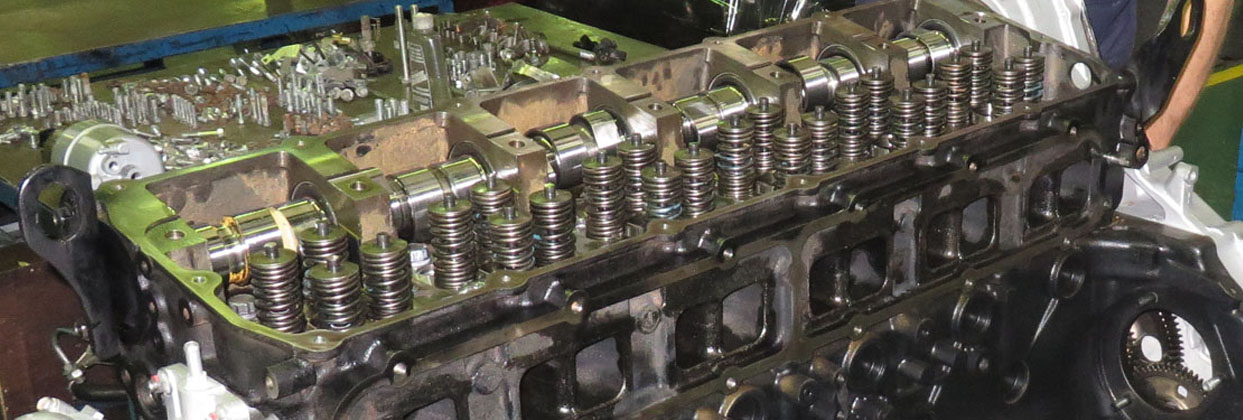

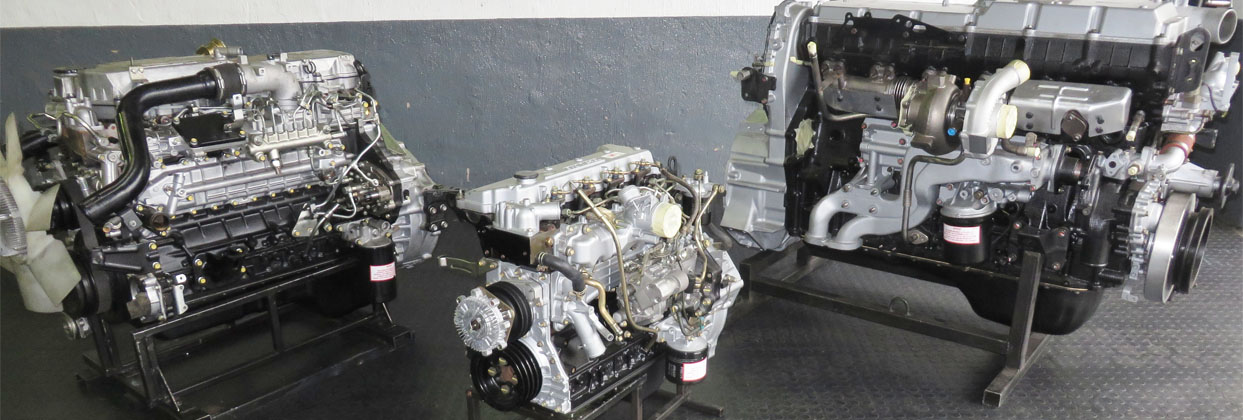

The Workshop consists of the Machine Shop and the Assembly departments which have a team of experienced artisans trained to ensure a high standard of workmanship and quality.

Stripping and Cleaning

Engines are stripped and thoroughly cleaned using the latest cleaning system which includes the Bake - Clean Oven, Shot Blaster and Shot Removal Tumbler Process. Once stripped, all the components are placed in a specially designed baking oven where all traces of sludge, grease and scale are burnt off. This method ensures that all inaccessible areas such as oil ....

Conrod Resizing

The Conrod Resizing machine as well as our Serration Cutting facility enables us to recondition conrods to OEM specification with minimum down-time. The Conrods supplied by our customers are examined for signs of stress (hairline cracks), twist, distortion which includes de-magnetis-ing. All small-end bushes are replaced, the conrod eye is also checked.

Crack Testing

All Core Components undergo a thorough test to detect cracks by means of an ultra violet / electro-magnetic process which is highly regarded in the automotive field. A hardness test is carried out on each journal, all radii are checked to OEM specification. if hardening is required the process is carried out and re-examined on the crack detector to ensure that no possible cracking has occurred...

|

|

|

|

|

|

|

|